No Spoking

Switch to T-L and recover your lost production.

Switch to T-L and recover your lost production.

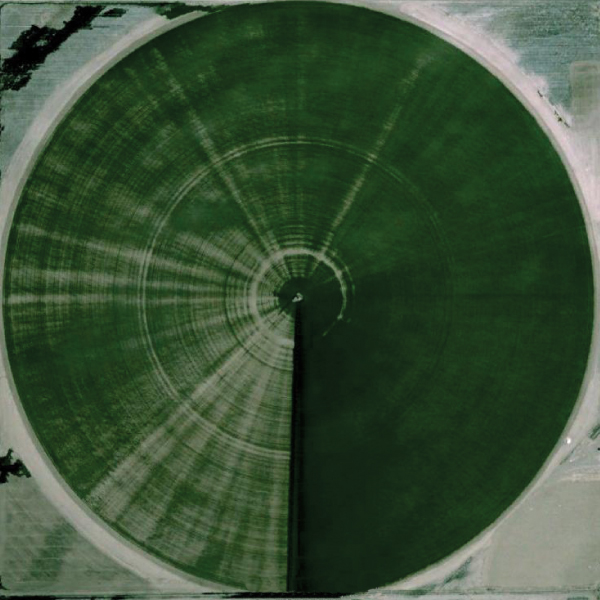

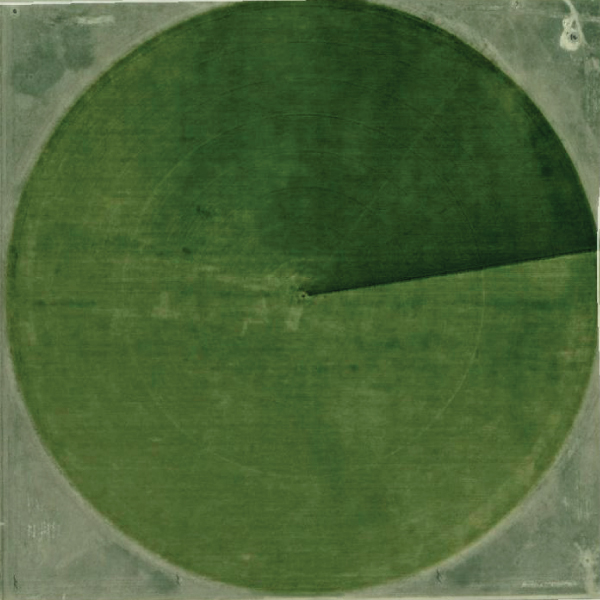

Notice the non-uniform water application of the center pivot circles shown. This is known as “spoking,” which results from the start-stop operation of an electric drive pivot system. An electric pivot starts and stops 2,880 times a day at the end tower alone. Michigan State University field research (Fusco, 1995) verified the significant effect of “spoking” and found application uniformity ranged from 15% to 85% on a leading manufacturers electric drive pivot. Call up Google Earth Maps on your computer and see for yourself.

Common sense would say the consequence of “spoking” is lost crop production and that production losses can be even greater if the system is being used for chemigation. Your investment in irrigation is significant, and is intended to maximize your economic return from your crop. However, the intermittent motion of an electrically powered pivot system can detract from your return, sometimes significantly.

History has shown that the start-stop motion is also detrimental to component life, increases mechanical problems, creates more expense, causes downtime, and generally makes irrigating miserable. Many growers have experienced these problems.